When designing a system, you want to guarantee the motor delivers the intended performance. Conditions and specifications ultimately dictate what type of motor best fits your needs when it comes to DC motors.

But, you have two choices:

- Brushed

- Brushless

Before looking at the difference between brushed and brushless, let’s review what a DC motor is. DC motors are direct current motors and considered electrical machines that transform electrical energy into mechanical energy.

Brushless DC motors have ditched the mechanical commutation in place of electrical, eliminating the usual wear and tear mechanical motors endure.

Recognizing brushless DC motors (BLDC motors) will be essential to performance and ensuring you have chosen the right solution.

To get started, let’s delve into qualities that identify BLDC motors as well as instances in which they are the more suitable option.

For starters, BLDC motors are growing in popularity thanks to their superiority in areas such as the ability to operate at high speeds, their higher efficiency, and better heat dissipation.

Additionally, they operate at higher performance levels in fields such as motor control technology.

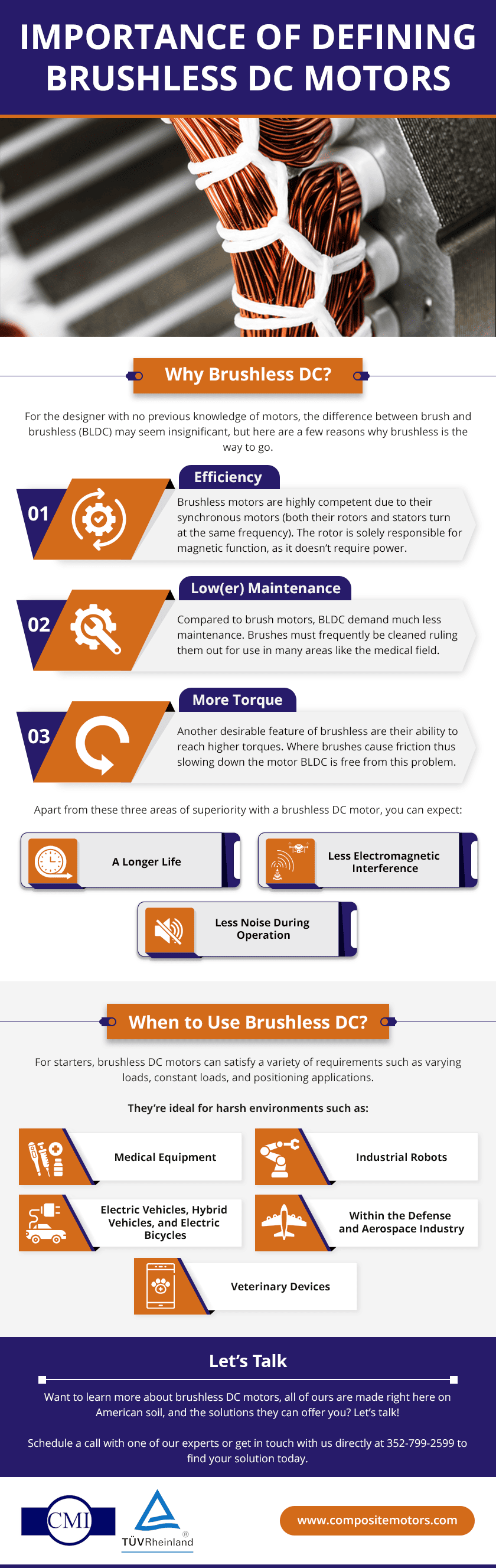

Why Brushless DC?

For the designer with no previous knowledge of motors, the difference between brush and brushless (BLDC) may seem insignificant, but here are a few reasons why brushless is the way to go.

- Efficiency: Brushless motors are highly competent due to their synchronous motors (both their rotors and stators turn at the same frequency). The rotor is solely responsible for magnetic function, as it doesn’t require power.

- Low(er) Maintenance: Compared to brush motors, BLDC demand much less maintenance. Brushes must frequently be cleaned ruling them out for use in many areas like the medical field.

- More Torque: Another desirable feature of brushless are their ability to reach higher torques. Where brushes cause friction thus slowing down the motor BLDC is free from this problem.

Apart from these three areas of superiority with a brushless DC motor, you can expect:

- A longer life.

- Less electromagnetic interference.

- Less noise during operation.

When to Use Brushless DC?

You understand the benefits, but you’re not quite sure when to use these BLDC motors. Here’s a simple guide to keep in mind when considering DC motors.

For starters, brushless DC motors can satisfy a variety of requirements such as varying loads, constant loads, and positioning applications. They’re ideal for harsh environments such as:

- Medical equipment

- Industrial robots

- Electric vehicles, hybrid vehicles, and electric bicycles

- Within the defense and aerospace industry

- Veterinary devices

Defining the Brushless Motor

In blog articles that follow, we will present a procedure for defining a permanent magnet motor. These blogs will be written for the designer who has no prior knowledge of motors as well as the expert who needs a refresher. They will help you define a motor for your mechanical systems.

Let’s Talk

Want to learn more about brushless DC motors, all of ours are made right here on American soil, and the solutions they can offer you? Let’s talk!

Schedule a call with one of our experts or get in touch with us directly at 352-799-2599 to find your solution today.