ABOUT CMI

Our story is a long one and while the years have brought many changes, from our company name to our industry, we have never faltered in our mission to deliver highly designed and performing custom solutions.

We began as Joburn Tool in 1966 in Attleboro, Massachusetts working in the tool and die business before taking the steps toward manufacturing semiconductor packaging materials for the electronics industry as Composite Technical Alloys. After decades in the industry, we created Composite Modules, Inc. which was followed by the creation of our sister company, Composite Motors, Inc.

Since 1965, we have been committed to delivering high quality and high precision electronic products for extreme environments. Composite Motors has met the continuous demand from industry leaders for smaller size, greater functionality, and innovative electronic devices that operate in harsh environments.

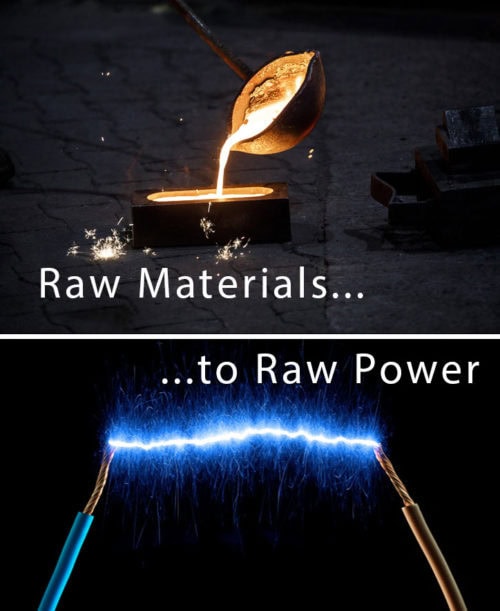

Vertically Integrated Manufacturing

Composite Motors is proud to say that all of our products are made right here on American soil which gives us a unique edge amongst competitors. Apart from producing and using American made components and parts we also pride ourselves on total commitment to excellent customer service. All of our clients have direct access to top-level employees and will find that our approach allows for flexibility and personalization to every project.

Composite Motors’ corporate office is located in Brooksville, Florida and has an additional seven buildings with 250,000 square feet of manufacturing, engineering and production space.

Due to our company being completely vertically integrated, Composite Motors holds several U.S. and foreign patents; including:

- 6,538,356 Electric machine using composite blade structure

- 6,889,420 Method for making a stator for an electric machine

- 7,608,963 Crimped rotor for an electric brushless direct current motor

- 8,028,396 Automatic wire winding of inside brushless stator

- 8,250,733 Automatic winder for an inside brushless stator

- CA 2,351,812 Electric Machine Using Composite Blade Structure, Canada

- EP 1168574 Electric Machine Using Composite Blade Structure, Europe

- JP 4471538 Electric Machine Using Complex Blade Structure , Japan

All raw materials for hermetic enclosures, power dissipation substrates and electrical interconnect junctions are processed by Composite Motors.

Additionally, our products are designed and built in-house, including tooling for stamping and assembly of:

- Stators

- Rotors

- Winding equipment

- Injection molds

- Circuit design

- Board layout

- Power planes

AMERICAN MADE

PRECISION BUILT

QUALITY FOCUSED

CUSTOMER CENTRIC

To learn more about our unique solutions get in touch with one of our experts to find out how we can serve you.