If you need an electrical motor or controller designed and manufactured just for your project, you’ve come to the right place!

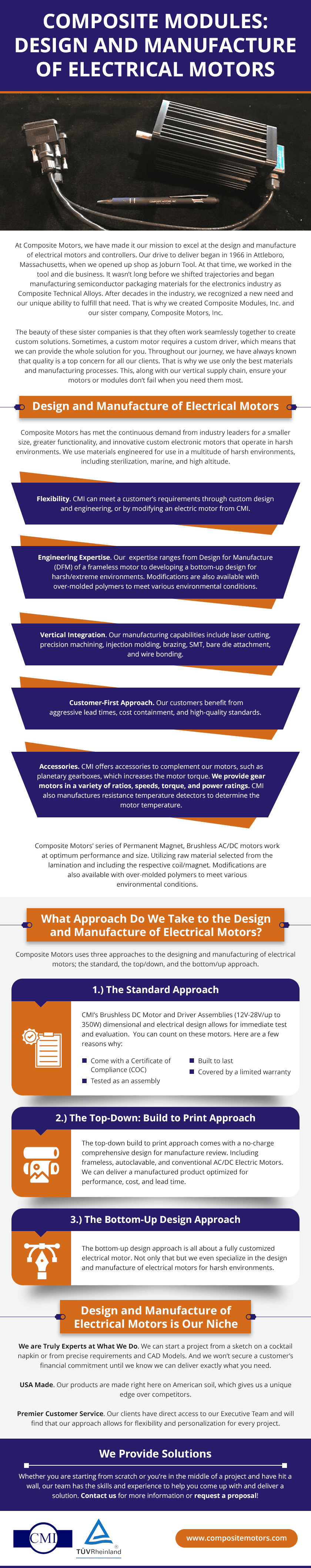

At Composite Motors, we have made it our mission to excel at the design and manufacture of electrical motors and controllers. Our drive to deliver began in 1966 in Attleboro, Massachusetts, when we opened up shop as Joburn Tool. At that time, we worked in the tool and die business. It wasn’t long before we shifted trajectories and began manufacturing semiconductor packaging materials for the electronics industry as Composite Technical Alloys. After decades in the industry, we recognized a new need and our unique ability to fulfill that need. That is why we created Composite Modules, Inc. and our sister company, Composite Motors, Inc.

The beauty of these sister companies is that they often work seamlessly together to create custom solutions. Sometimes, a custom motor requires a custom driver, which means that we can provide the whole solution for you. Throughout our journey, we have always known that quality is a top concern for all our clients. That is why we use only the best materials and manufacturing processes. This, along with our vertical supply chain, ensure your motors or modules don’t fail when you need them most.

Design and Manufacture of Electrical Motors

Composite Motors has met the continuous demand from industry leaders for a smaller size, greater functionality, and innovative custom electronic motors that operate in harsh environments. We use materials engineered for use in a multitude of harsh environments, including sterilization, marine, and high altitude.

CMI offers customers the flexibility to manufacture a product that meets a customer’s design criteria or select/modify an electrical motor from CMI. Our Engineering expertise ranges from Design for Manufacture (DFM) of a frameless motor to developing a bottom-up design for harsh/extreme environments.

Due to CMI’s vertically integrated manufacturing capabilities, including laser cutting, precision machining, injection molding, brazing, SMT, bare die attachment, and wire bonding; our customers benefit from aggressive lead times, cost containment, and high-quality standards.

Composite Motors’ series of Permanent Magnet, Brushless AC/DC motors work at optimum performance and size. Utilizing raw material selected from the lamination and including the respective coil/magnet. Modifications are also available with over-molded polymers to meet various environmental conditions.

CMI offers accessories to complement our motors, such as planetary gearboxes, which increases the motor torque. We provide gear motors in a variety of ratios, speeds, torque, and power ratings. CMI also manufactures resistance temperature detectors to determine the motor temperature.

What Approach Do We Take to the Design and Manufacture of Electrical Motors?

Composite Motors uses three approaches to the designing and manufacturing of electrical motors; the standard, the top/down, and the bottom/up approach.

1.) The Standard Approach

CMI’s Brushless DC Motor and Driver Assemblies (12V-28V/up to 350W) dimensional and electrical design allows for immediate test and evaluation. You can count on these motors. Here are a few reasons why:

- Come with a Certificate of Compliance (COC)

- Tested as an assembly

- Built to last

- Covered by a limited warranty

2.) The Top-Down: Build to Print Approach

The top-down build to print approach comes with a no-charge comprehensive design for manufacture review. Including frameless, autoclavable, and conventional AC/DC Electric Motors. We can deliver a manufactured product optimized for performance, cost, and lead time.

3.) The Bottom-Up Design Approach

The bottom-up design approach is all about a fully customized electrical motor. Not only that but we even specialize in the design and manufacture of electrical motors for harsh environments.

Design and Manufacture of Electrical Motors is Our Niche

We are truly experts at what we do. For instance, we can start a project from a sketch on a cocktail napkin or from precise requirements and CAD Models. And we won’t secure a customer’s financial commitment until we know we can deliver exactly what you need.

We do it all from our vertically integrated supply chain. Furthermore, our products are made right here on American soil, which gives us a unique edge over competitors. Located in Brooksville, Florida, the Composite Motors’ corporate office also has seven additional buildings with 250,000 square feet of manufacturing, engineering, and production space.

Apart from producing and using American-made components and parts, we also pride ourselves on total commitment to premier customer service. Also, all of our clients have direct access to our Executive Team and will find that our approach allows for flexibility and personalization for every project.

We Provide Solutions

Whether you are starting from scratch or you’re in the middle of a project and have hit a wall, our team has the skills and experience to help you come up with and deliver a solution. Contact us for more information or request a proposal!