Since 1965, Composite Motors, Inc. (CMI) has delivered high-precision, quality electronic products that can handle the requirements of extreme environments. We serve various industry-leading companies, providing greater functionality, smaller sizes, and innovative electronic devices for peak performance in harsh operating conditions.

We offer unsurpassed vertical integrated manufacturing and engineering services to ensure total customer satisfaction. All CMI products are made in the U.S. We process all raw materials for electrical interconnect junctions, power dissipation substrates, stators, and hermetic enclosures for enhanced performance.

We design and manufacture the following products in-house:

At CMI, we strive to deliver quality-focused, precision-built products with a customer-centric mindset. We use our wealth of knowledge and resources to provide customers with high-quality, low-failure-rate products. Our clients also receive direct access to top-level staff, allowing for personalization and flexibility in every project.

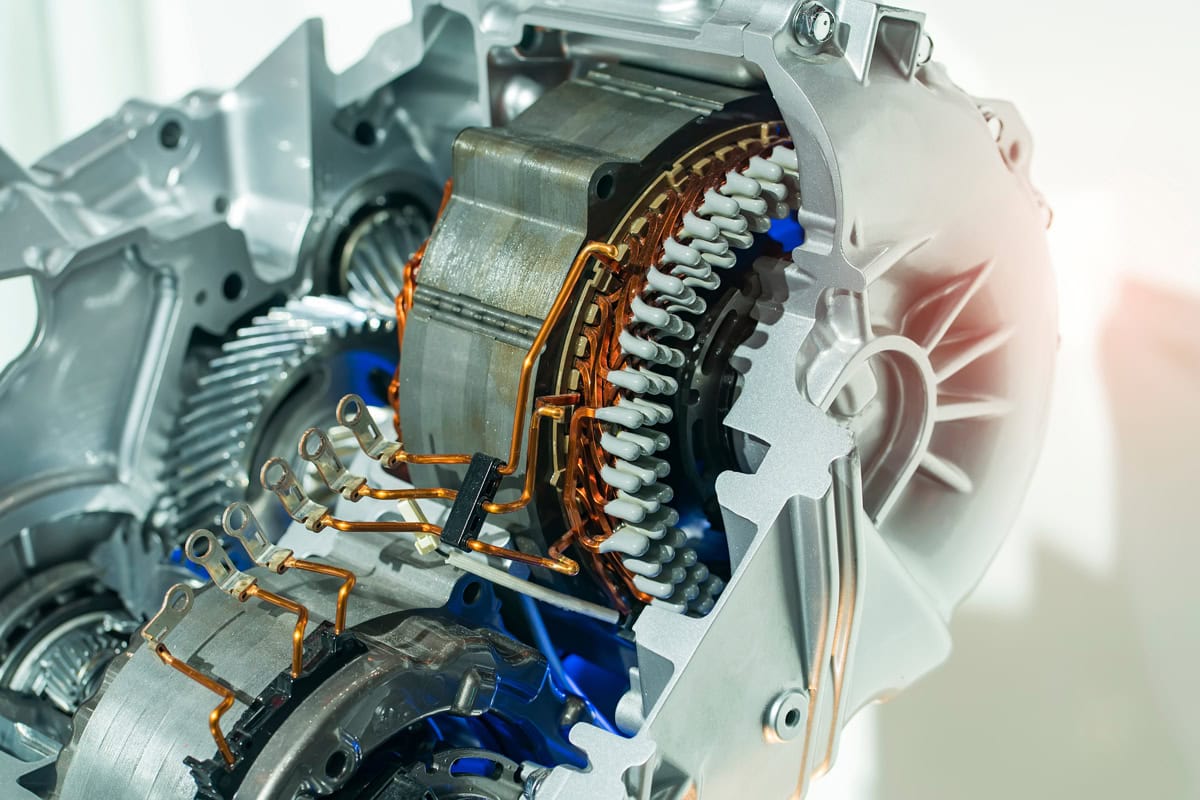

Custom Electric Motors

The high-density slot on our motors uses specialized in-house winding equipment and custom stator designs to produce formidable power densities. We offer gear motors at various speeds, ratios, power, and torque ratings.

Benefits of Our Custom Electronic Motors

All CMI motors are tested for their ability to withstand extreme ambient temperature conditions, saltwater submersion, and other harsh environments.

Our motors offer the following benefits:

- Customization. We tailor motor designs to meet the demands of various applications. Custom designs can provide a superior solution that can be adapted to realize the desired product characteristics.

- Designed for Harsh Environments. CMI motors have been designed to withstand the steam sterilization process associated with autoclaves.

- Greater Flexibility. CMI motors can manufacture motors from 1 inch to 8 inches in diameter.

- Compatibility. CMI motors have been designed in conjunction with hermetically packaged motor drivers.

Our custom electric motors are all made here in America. We offer brushless and permanent magnet motors. We also offer built-to-print AC motors.

Brushless DC Motors

Common uses of BLDC motors in industrial engineering include:

- Motion & Control for Medical Devices

- Actuators for Industrial Robots

- Extruder Drive Motors

- Feed Drives for CNC Machine Tools

- Linear Actuators

- Motion Control

- Servomotors

BLDC motors replace the mechanical commutator used in conventional motors with an electronic device that improves system durability, reliability, and efficiency. They can be lighter and smaller than brush-type motors while offering similar power output, which is ideal for applications with limited space.

Our custom brushless DC motors offer additional advantages to customers, including:

- High Efficiency

- Low Maintenance

- Long Life

- Enhanced Torque

- Quiet Operation

- High Speed

- Less Electromagnetic Interference

BLDC motors are the preferred choice for the following applications and industries:

Medical Devices

Military & Defense

Industrial Equipment

Aerospace

Automotive Manufacturers

Commercial Electrical Products

Fans, Pumps, and Blowers

Home Appliances

BLDC Motor Controllers

A BLDC motor controller is the electronic device responsible for monitoring the successful operation of brushless DC (BLDC) motors. This device controls the speed and torque of the motors and can reverse, start, and stop its rotation.

BLDC motor controllers from CMI offer the following advantages:

- Hermetic Packaging

- Speed-Torque Control

- Efficiency

- Reliability

- Flexibility

- Dynamic Response

- Decreased Electromagnetic Interference (EMI)

Our BLDC motor controllers meet the demands of various industries, such as medical devices, industrial automation systems, aerospace, robotics, and electric vehicles.

Hermetically Sealed Packaging

Hermetically sealed packaging involves creating an airtight seal with one of the following materials:

- Propriety Metal Alloys

- Ceramics

- Glass Seals

Air or water exposure can damage a delicate connection and stop it from properly working. Semiconductors are one of the most common products that can sustain considerable damage through direct contact with water or water vapor. Hermetic seals can be used to repair these and other damages that might occur during operation.

At CMI, our state-of-the-art machinery incorporates the latest technologies, including but not limited to the following:

CMI utilizes unique components and materials like hermetic glass-sealed lids and packages with verifiable leakage rates at the limits of all available tests.

Quality Brushless DC Controllers & AC/DC Motors by CMI

Composite Motors, Inc. offers a unique line of high-performance BLDC motor controllers, brushless DC motors, and custom electric motors. Our available models include both Hi-Rel hermetically sealed packaging and printed circuit types. Power ranges from integral to fractional horsepower.

CMI employs cutting-edge advanced controller technologies that can be integrated with our proprietary high-power drives. All CMI controllers are designed to tolerate the harshest and most hostile environments. Our drivers are hermetically sealed, and the entire unit is Class B Autoclavable at 134 C.

At CMI, we understand each team, project, and mission has unique demands and specific requirements to ensure success. Contact our team of experts today to explore the full spectrum of support from integration, design, and maintenance capabilities.

We look forward to working with you and developing unique solutions that meet the demands of your next project.